HOW FEATHER DUSTERS ARE MADE

South Africa is virtually the only place where ostriches are farmed

for feathers and other products and where feather dusters are made.

Feather dusters sold in the United States and other countries under the

brand names of major manufacturers of home products are purchased

directly from South African wholesalers.

The plants in South Africa that make feather dusters both process

the feathers and assemble the dusters. Ostrich feathers are plucked

from live birds cared for on large farms of thousands of birds. These

farms also produce leather and meat from separate stocks of ostriches.

The birds have many layers of feathers for insulation that range in

size from very short to extravagantly long. The processing and assembly

plant receives the feathers in bulk shortly after they have been

plucked from the farmed birds.

Handles for feather dusters are either wood or plastic. Wooden

handles are also made in South Africa and are received at the feather

duster plant as finished products. Specialized suppliers use hardwood

from several species of South African trees. Cured wood is cut into

blocks of suitable lengths and dimensions and turned on lathes to shape

the handles. Holes are drilled in the tops of the handles so loops can

be added for hanging the feather dusters. After the handles are turned

and drilled, they are sanded in machines that sand in several stages

using finer and finer grades of sandpaper. Finally, the handles are

stained and varnished. After drying, they are packaged and shipped to

the feather duster plant.

Plastic handles are made of Marlex plastic and are injection-molded

at Asian plants. Other plastic parts include ferrules, the caps that

fit over the feathers where they join the handles, and the hanging

loops. Again, the feather duster maker receives these not as true raw

materials but as supplied parts.

Contact glue is purchased in bulk from a specialized glue

manufacturer. Contact glue is semi-sticky and is not designed to be the

only fixative that holds feathers on the handles. Low carbon steel wire

provides the strong binding. The sizes of wire are described in gauges

that are measures of the diameter of the wire. Feather dusters are made

with 16-gauge wire, a relatively fine size equaling 0.001 in (0.03 mm)

in diameter. A wire manufacturer ships the wire to the feather duster

factory on large reels or rolls.

Design

The design of feather dusters made with ostrich feathers is almost

unchanged since about 1900. Probably the biggest design change in their

history was the production of some lines of dusters with plastic

handles when plastic design improved rapidly after World War II. Some

plastic dusters are made in retractable designs with hollow handles

that slip down over the feathers. Feather duster manufacturers will

make design changes specifically for clients. These special orders are

made for companies like large janitorial services or suppliers.

Design changes are more frequent for less expensive dusters made

with turkey feathers. Usually, these feathers are dyed, and colors are

changed occasionally depending on popular decorator colors. Handles for

these dusters are modified in length and curvature to attempt to

interest more purchasers. Foam grips on the handles are an example of a

recent design change made to be both functional and eye-catching.

Interestingly, the care of ostriches is a "design change" that

manufacturers are beginning to practice. Ostrich feather products have

very little value compared to meat and leather from the birds; meat

production generates 200 times more income than feather-related

manufacture. Consequently, farmers and manufacturers who maintain

flocks of ostriches are learning how to improve feather production.

Ostrich care has changed little since ostrich farming began on a large

scale, also about 100 years ago. Typically, it takes 12-14 months for

an ostrich's feathers to grow enough so they can be harvested. If the

birds are given quality feed and improved attention at the farms, this

time can be reduced to two months and feather quality also improves.

Workers in the feather duster plant are now also paid far more than

South Africa's minimum wage, so they invest more care in the plucking

and processing of the feathers. Designs of actual dusters made with

ostrich feathers may be forced to change in the future if costs of

materials skyrocket.

The Manufacturing

Process

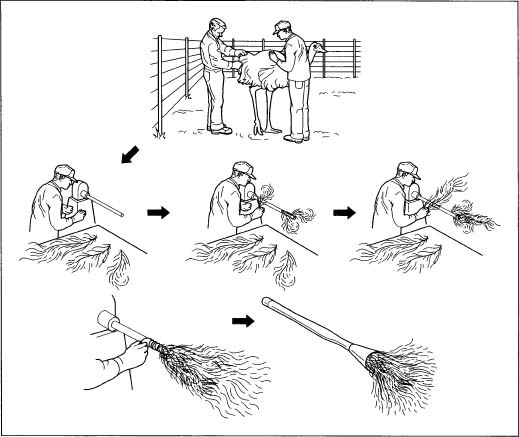

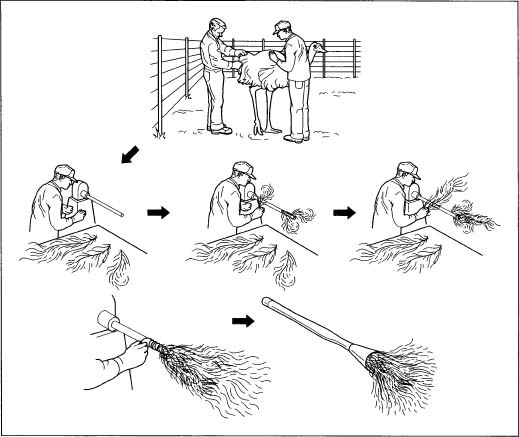

- At the ostrich farm, individual birds are herded into corral-like

pens where handlers pluck the birds to harvest the feathers. Feathers

are plucked from the bodies of the birds where the ideal types of

feathers (and those less likely to be damaged) grow but also from over

the birds' bodies so no single

The feathers are plucked from the ostrich and then applied to the handle.

area is denuded. When feathers are plucked from slaughtered

birds, damaged or heavily soiled feathers and types of feathers that

are not useful are avoided. After the best feathers are selected, the

remaining feathers are stripped off and destroyed before the hide is

removed for tanning and the meat is processed. - Plucked feathers are delivered in bulk to the factory. They are

washed, fumigated, graded by quality, and sorted by size. By the time

the feathers are ready to be delivered to the duster assembly stations,

they have been handled by at least 50 people.

- At each assembly station, about I oz (25 g) of feathers have been

sorted by size and are ready to be fixed to the handle. The handle is

held in a small, lathe-like device that the worker can turn as feathers

are fixed to the handle. Contact glue is spread on the bottom end of

the handle. The contact glue is not very sticky and does not dry with a

firm seal. It is only a temporary method of holding the feathers in

place until wire can be wrapped around them.

- After the first application of contact glue, the worker adds a

small layer of short feathers. More glue is spread, and a layer of

slightly longer feathers is put in place. The turning device keeps the

handle rotating, more glue is applied, and a layer of even longer

feathers is added. The process continues until all of the feathers

previously

sorted by length have been fixed to the duster handle.

- At each workstation, a roll of steel wire is mounted overhead above

the turning device. As the layers of feathers are added, the worker

wraps wire around the feathers already in place and ties and cuts the

wire. Wire is not used with each layer, but it is applied several times

during the process of building up the feather layers and after the last

layer is added.

- After the final feathers and wire are in place, a plastic cap

(ferrule) is pushed over the top of the feathers and wire. Covering the

wire makes the feather duster more attractive, but the cap also

prevents any wire ends from hurting the person who will use the duster.

A plastic cap is used with both wood and plastic handles. In fact, the

supplier packs a plastic cap with each handle so they are ready for

assembly. Loops for hanging the duster are tied through predrilled

holes or formed in the handles.

- Finished feather dusters are collected from the workstations and

taken to the packaging department. Plastic sleeves are fitted over the

feathers to cover them completely. The sleeves fit snugly but not too

tightly to hold the feathers in place but not break them, and the

sleeves are longer than the feathers so their tips do not get bent or

broken. Other wrappings are put over the handles. Feather dusters are

not packed and labeled for individual sale. Instead, they are packed in

bulk in cardboard shipping boxes for distribution to consumers who use

large numbers of feather dusters, like building maintenance firms and

supply houses for janitors. They are also shipped to retailers who may

change the packaging and add their own labels.

Quality Control

The handles, plastic ferrules, and hanging loops are inspected

before they are distributed to the assembly stations. The process of

controlling the quality of the feathers is continuous because the 50

people who handle the feathers during the cleaning, sorting, and sizing

steps are responsible for rejecting poor quality feathers.

Inspectors observe all stages of feather processing and duster

assembly. They intervene if they see inadequate materials or methods

that the worker overlooks. The inspectors also perform final

inspections of the finished feather dusters and look at each product

before it is boxed.

Byproducts/Waste

Production of feather dusters does not generate any byproducts

although feathers themselves are harvested during other processing of

products from ostriches, such as meat. Waste from the manufacture of

feather dusters consists mostly of feathers. Over 50% of those plucked

from live birds or saved from meat-producing stock are wasted because

of damage or poor quality. Feather waste is disposed by burning, which

is legal in South Africa. No wood or plastic waste is generated because

these components are made by outside suppliers and are not trimmed or

modified at the feather duster factory. There are also no metal

trimmings from the steel binding wire or wasted glue except for minor

spillage.

Employees are also exposed to few hazards. Safety guards and

emergency stops on the lathe-like turning devices prevent injury. The

steel wire is enclosed in a plastic cover until it is near the handle

that is being worked. The worker does not need to wear gloves to wind

the wire on the handle although goggles are worn for eye protection

because of the proximity of the wire. The glue is also inert and does

not present hazards due to fumes or skin contact. Dust from feather

processing is kept completely away from the duster floor, and, in the

feather-processing area, it is swept up frequently and collected for

burning with the other feather waste.(www.madehow.com)

Facebook

Facebook Twitter

Twitter Contact Us

Contact Us